Characteristics of Heat Transfer Printing on fabric in Kharkov and Kremenchug

1. Printing from 1 piece. Heat Transfer Printing on fabric allows you to implement individual design of prints, bright prints and original solutions. With small quantities of vector images, which are expensive to print using the silk screen printing method, it is advantageous to use special thermo films.

2. Covering effect (the fabric does not break through the film).

3. Species and color varieties of films. A new direction in thermal printing is printing with reflective films. Such films will save the lives of pedestrians on the roads, especially children. Reflective marking as a mandatory attribute of children's clothing is a matter of state regulation. The use of thermo films allows you to create beautiful and original prints and logos, and not to use only attached reflective tape.

Our recommendations:

Printing on fabric with thermo films is used in promotional gifts, interior decoration, gift wrapping and in the sewing industry. For example, marking and logging of special professional clothes. Printing on cut and printing on finished products, printing on the surfaces without joints and fittings. In the personification of working wear and clothing services used high-quality Italian films, which ensure long-term using. Individual personification of sportswear. Logos of sports teams, names and numbers of players and slogans; also optimal printing with thermo films, taking into account numerous washes. Heat Transfer Printing on fabric is used in designer clothes, in limited collections, in the preparation of photo shootings.

Modern methods of printing on the fabric are very diverse, but for the most part, they assume printing on the cut or roll printing of the fabric. Printing on ready-made T-shirts, children's or women's clothes, overalls, promo and promotional clothing, souvenirs, etc. is possible due to thermal transfer printing, provided that there is a flat surface without buttons and additional parts or seams.

Modern methods of printing on the fabric are very diverse, but for the most part, they assume printing on the cut or roll printing of the fabric. Printing on ready-made T-shirts, children's or women's clothes, overalls, promo and promotional clothing, souvenirs, etc. is possible due to thermal transfer printing, provided that there is a flat surface without buttons and additional parts or seams.

Printing on the edge is considered more desirable, because when exposed to high temperatures and pressure there are no interfering elements, the logo is transferred more qualitatively.

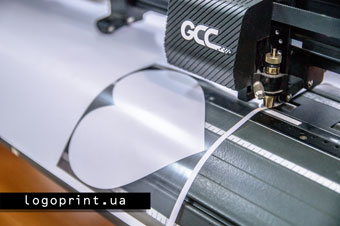

For thermo-printing, small characters can also be a limitation, which can not be cut and carefully selected, less than 1 mm thick. Raster images can not be trimmed, they are not suitable for thermal transfer. Complex multicolored images can not always be successfully matched, for them it is optimal to choose other printing methods.

Thermal printing is widely used for making samples, when starting a new collection, for photo sessions in online stores, in sportswear, overalls. We provide an additional service of trimming thermofilms for self-transfer. You do not need to cut or sew the whole lot, and use logos for less than necessary.