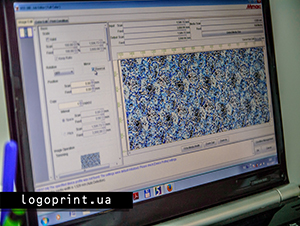

Characteristics of large-format Dye Sublimation Printing on fabric in Kharkov and Kremenchug

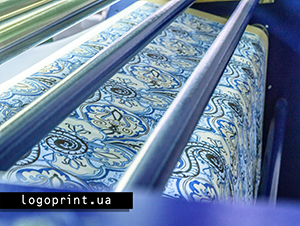

1. White synthetic base (synthetic textile, contains more than 80% of synthetic). If textile contains less synthetic fibers, the print is more pale and unstable. The white color is required for accurate color reproduction. Depending on the layout, sometimes you can use completely pale colors of the fabric, such as: light beige and gray, light blue and pink. White synthetic fabric: gabardine, satin, diving, mesh, velour and many other fabrics, which are different in density and texture, allow you to get new unique textile fabrics.

2. The fabric must withstand 200 C. Most synthetic fibers have a high tolerance for high temperature, but it is difficult to avoid shrinkage. All fabrics for sublimation transfer are pre-tested. When printing on the cut, the size of shrinkage is agreed in advance. High temperature and pressure ensure image durability under different operating conditions. The sublimation printing of flags is the most striking example of the durability of a large-format sublimation image.

Our recommendations:

The main competitive advantage of Dye Sublimation Printing on fabric is the ability to print different prints in single copies. The cost of printing doesn’t depend on the type of prints; it is directly proportional to how many square meters of printing. An individual approach to each customer guarantees high quality printing on fabric. Our special offers: roll-to-roll transfer, printing on a cut, dye sublimation printing of labels and ribbons, making stripes by sublimation. The wide range of ways of the sublimation printing on fabric is not fully implemented. We invite you to the LOGOPRINT company’s offices in Kharkov and Kremenchug, for free testing of your fabric and the selection of the optimal method of printing.